Application

Motorcycle

Writer: admin Time:2022-06-28

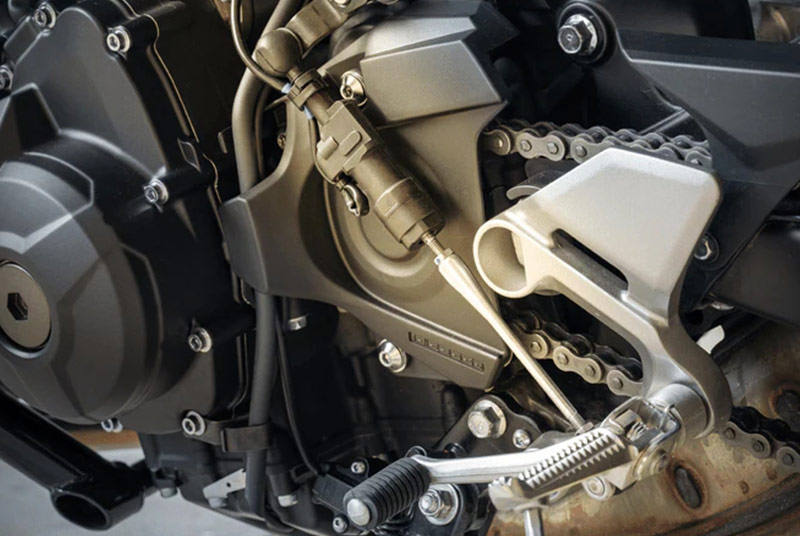

The motorcycle gearbox is divided into input and output shafts, and the common material of the box is aluminum alloy. Professional motorcycle players pursue high speed and high power, but the traditional aluminum alloy box cannot meet the high speed and high torque performance requirements. It is necessary to use alloy steel as the box body, but the thermal expansion coefficient of alloy steel is higher than that of the bearing. For bearings installed at room temperature, when the temperature of the box body rises, the fit between the outer ring of the bearing and the seat hole of the box body will Looseness and high-speed rotation will cause the outer ring of the bearing to creep, and the cage will fail early due to fracture and deformation. The solutions in the motorcycle manufacturing industry at home and abroad are to add a top pin to the outer circle of the bearing and an overhead groove for the box seat hole. In order to make up for the cracking of the box caused by the stress concentration of the pin groove, the wall thickness of the box can only be increased, which will inevitably lead to an increase in the total weight of the gearbox. This is contrary to lightweight.

The developed bearing with expansion compensation ring is used in the box of high-speed and high-power motorcycles, and has passed various tests such as conventional road tests, bumpy road tests, high temperature and high speed, and extreme speed and sudden braking. The weight of the entire box is reduced by 10 kilograms, the noise of the whole vehicle is reduced by 5 decibels, and the efficiency of box processing and gearbox installation is improved.

CATEGORIES

LATEST NEWS

CONTACT US

QQ: 764282916

Phone: 0086 13561463111

WhatsApp: 13561463111

Email: haidingzc@163.com

Add: Bearing Pioneer Park, Yandian Town, Linqing City, Liaocheng City, Shandong Province